High-Quality Electrical Wire Fiberglass Insulation Sleeving for Maximum Protection

By:Admin

{Company Name} has been at the forefront of producing high-performance electrical wire fiberglass insulation sleeving for over two decades. With a strong focus on research and development, the company has continually improved its products to meet the ever-changing demands of the electrical industry.

Their electrical wire fiberglass insulation sleeving is designed to provide reliable insulation in a wide range of temperatures, making it suitable for use in various applications such as automotive, aerospace, electronics, and industrial equipment. The sleeving is manufactured using high-quality fiberglass materials that are resistant to heat, chemicals, and abrasion, ensuring the long-term performance and safety of electrical components.

In addition to its insulation properties, {Company Name}'s electrical wire fiberglass insulation sleeving is also highly flexible, allowing for easy installation and maintenance. The sleeving can be easily cut to size and bent around tight corners without compromising its integrity, making it a cost-effective solution for protecting and insulating electrical wiring in confined spaces.

Furthermore, {Company Name} is committed to sustainability and environmental responsibility in its manufacturing processes. The company utilizes advanced technologies to minimize waste and emissions, and all of its products comply with international environmental regulations and standards. This dedication to sustainability has earned {Company Name} a reputation for being an environmentally conscious and socially responsible manufacturer in the electrical industry.

As the demand for high-quality electrical wire insulation continues to grow, {Company Name} remains dedicated to meeting the needs of its customers with innovative and reliable products. With a strong emphasis on quality control and customer satisfaction, the company has built a loyal customer base that trusts in the performance and reliability of its electrical wire fiberglass insulation sleeving.

In conclusion, {Company Name} is a leading manufacturer of electrical wire fiberglass insulation sleeving, offering a wide range of high-performance products designed to meet the stringent requirements of the electrical industry. With a focus on quality, flexibility, and sustainability, the company has positioned itself as a trusted and reliable supplier of electrical insulation solutions for a variety of applications. As the industry continues to evolve, {Company Name} is poised to remain at the forefront of innovation and excellence in electrical wire insulation technology.

Company News & Blog

Discover the Revolutionary Pyrolytic Gasket With Clips for Unmatched Performance

Title: Innovative Pyrolytic Gasket Revolutionizes Industrial Sealing SolutionsIntroduction:[Company Name], a leading provider of cutting-edge industrial solutions, has recently introduced a groundbreaking product that is set to revolutionize the manufacturing industry. The Pyrolytic Gasket with Clips is a game-changing sealing solution designed to enhance operational efficiency, safety and durability in a wide range of industrial applications.Pyrolytic Gasket With Clips: Unmatched Performance in Industrial Sealing[Company Name]'s Pyrolytic Gasket With Clips is a state-of-the-art sealing solution that combines advanced materials and innovative engineering techniques to provide unmatched performance in various industrial environments. This highly versatile gasket has been meticulously designed to withstand extreme temperatures, pressure differentials, and aggressive chemical exposure.Key Features and Benefits:1. Superior Heat Resistance: The Pyrolytic Gasket With Clips is specifically engineered to withstand extreme temperatures, making it ideal for applications that involve high-temperature environments. With a remarkable heat resistance of up to [specific temperature], this gasket ensures a reliable seal, minimizing the risk of leakages and equipment failure.2. Excellent Chemical Resistance: Composed of advanced materials, the Pyrolytic Gasket With Clips can withstand harsh chemical environments without compromising its sealing properties. This feature enables the gasket to maintain its structural integrity and effectiveness even when exposed to corrosive fluids and gases, thereby extending the operational lifespan of equipment.3. Robust Durability: Unlike traditional gaskets, the Pyrolytic variant boasts exceptional durability, ensuring a longer service life for industrial equipment. This innovative product resists wear and tear, reducing the need for frequent replacement and resulting in significant cost savings for businesses.4. Easy Installation and Maintenance: Designed with convenience in mind, the Pyrolytic Gasket With Clips offers easy installation and maintenance. The integrated clips provide secure attachment, allowing for quick and hassle-free gasket replacement, minimizing downtime and increasing overall operational efficiency.Applications:The Pyrolytic Gasket With Clips finds its applications across a wide spectrum of industries and sectors. Here are some key areas where businesses can benefit from this groundbreaking sealing solution:1. Petrochemical Industry: In high-pressure and temperature environments commonly found in refineries and petrochemical plants, the Pyrolytic Gasket With Clips provides a reliable and durable seal for flanges, valves, and other critical connections.2. Energy Generation: Power plants and energy facilities can rely on the Pyrolytic Gasket With Clips to seal steam, gas, and oil pipelines, ensuring leak-free operations in extreme conditions.3. Automotive Manufacturing: The gasket's superior heat resistance makes it an excellent choice for sealing engine components, exhaust systems, and other crucial connections in the automotive industry.4. Pharmaceutical and Food Processing: The Pyrolytic Gasket With Clips offers excellent chemical resistance, making it an ideal choice for pharmaceutical and food processing applications where strict sanitary standards must be met.Conclusion:[Company Name]'s introduction of the Pyrolytic Gasket With Clips represents a significant advancement in the industrial sealing solutions sector. The gasket's combination of heat resistance, chemical resistance, durability, and ease of installation sets a new standard in sealing technology. By preventing leakages and equipment failures, this innovative product helps businesses enhance safety, operational efficiency, and cost-effectiveness across various industries. As the market increasingly demands reliable and long-lasting sealing solutions, the Pyrolytic Gasket With Clips is positioned to play a pivotal role in meeting these requirements and driving forward industrial progress.

Protect Your Hoses with Heat Resistant Sleeves

Heat Resistant Sleeve for Hose: A Solution to Protect Your MachineryMachinery and equipment are an essential part of modern life, and they require constant upkeep to function efficiently. When it comes to high-temperature applications like industrial pipes, hoses, and wires, they need to be protected from heat damage. The good news is that there is a solution for this - a heat resistant sleeve for hoses.{Company Name}, a leading manufacturer of high-quality thermal insulation products, has recently added a heat resistant sleeve for hoses to its product portfolio. The sleeve is designed to protect hoses, wires, and cables from temperatures up to 500°F (260°C), making it ideal for use in industries such as oil and gas, chemicals, and manufacturing.The heat resistant sleeve is made of high-quality materials that resist chemical degradation, ozone, and UV radiation. It is also abrasion-resistant and provides excellent insulation, reducing energy costs and increasing the lifespan of hoses and cables.{Company Name} ‘s heat resistant sleeve is highly flexible and easy to install, making it an ideal choice for retrofitting existing systems. The sleeve can be easily slipped over the hose or cable and secured with heat shrink tape, making it fast and reliable to install.One of the most significant advantages of using {Company Name}’s heat resistant sleeve is that it significantly reduces the risk of hose failure due to heat damage. Often, high-temperature applications result in hoses and cables getting brittle, cracked, or even melted. Such damage can cause leaks, system failures, and pose serious risks to workers and equipment. By using heat resistant sleeves, companies can protect their machinery and prevent such hazardous conditions from occurring.Heat resistant sleeve for hoses is an excellent investment for companies that value safety and efficiency. The sleeve not only offers protection against high temperatures but also extends the lifespan of hoses and cables, resulting in significant savings in replacement and maintenance costs.{Company Name}’s heat resistant sleeve for hoses is a product that meets the highest standards of safety and efficiency. It is designed to help companies reduce their carbon footprint and promote sustainable practices. As a premium insulation solutions provider, the company is committed to innovation, quality, and customer satisfaction.{Company Name} is a global leader in providing thermal insulation products that meet the requirements of diverse industries. The company offers a broad range of products, including heat resistant tapes, jackets, blankets, and sleeves. Their extensive product portfolio, along with their technical expertise, allows them to provide custom solutions tailored to each client’s unique requirements.In conclusion, the heat resistant sleeve for hoses offered by {Company Name} is a highly beneficial investment for companies that value safety, efficiency, and sustainability. The sleeve protects machinery and extends the lifespan of hoses and cables, which saves costs on replacements and maintenance. As a leading global provider of insulation solutions, {Company Name} is committed to providing innovative, high-quality, and reliable products that meet and exceed industry standards.

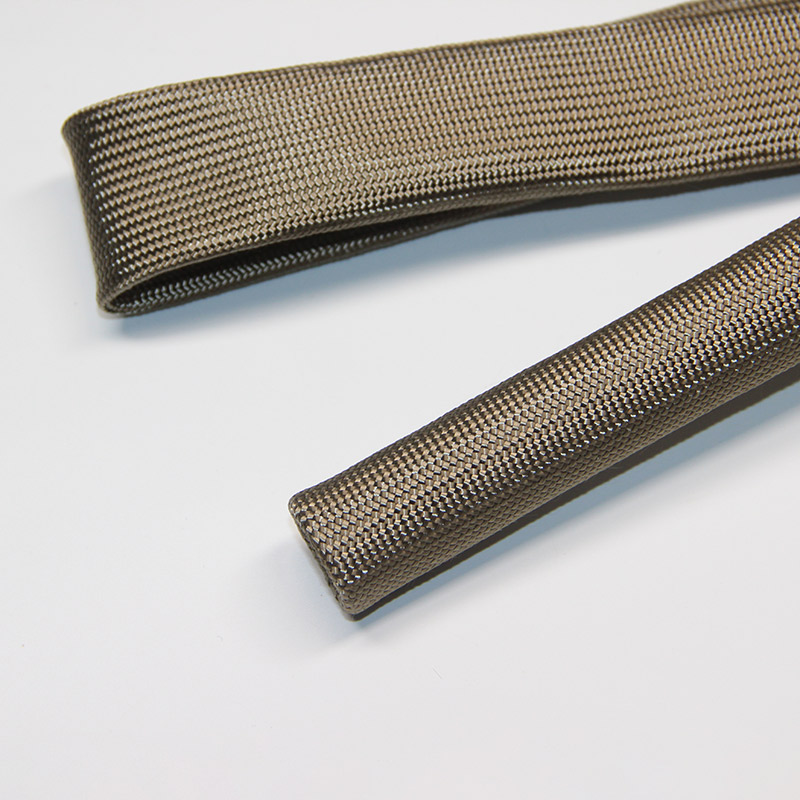

Durable Braided Nylon Wire Sleeving for Cable Protection

Braided Nylon Wire Sleeving Provides Durable Cable ProtectionIn today's fast-paced and technology-driven world, the demand for reliable and durable cable protection solutions is higher than ever. As the use of electronic devices continues to rise, the need for high-quality wire sleeving has become essential for both businesses and individuals. With this in mind, {Company Name} has emerged as a leading provider of braided nylon wire sleeving, offering a wide range of solutions to meet the needs of various industries.Established in {year}, {Company Name} has built a strong reputation for delivering top-notch wire sleeving products that are engineered to provide maximum protection for cables and wires. The company prides itself on its commitment to quality and innovation, constantly striving to develop cutting-edge solutions that meet the evolving needs of its customers.One of the standout products in {Company Name}'s portfolio is its braided nylon wire sleeving, which is designed to provide exceptional protection and durability for cables. The braided construction of the sleeving makes it highly flexible, allowing for easy installation and maintenance of cables in various applications. The nylon material used in the sleeving is known for its resistance to abrasion, chemicals, and UV radiation, making it an ideal choice for demanding environments.In addition to its durability, {Company Name}'s braided nylon wire sleeving offers excellent expandability, allowing it to accommodate a wide range of cable diameters. This feature makes it a versatile solution that can be used in a variety of industries, including automotive, aerospace, telecommunications, and more. Whether it's for cable management in a vehicle or protection of essential wiring in an aircraft, {Company Name}'s braided nylon wire sleeving delivers the reliability and performance that customers expect.Furthermore, {Company Name} offers customization options for its braided nylon wire sleeving, allowing customers to tailor the product to their specific requirements. Whether it's a particular color, length, or diameter, the company's engineering team works closely with each customer to ensure that the sleeving meets their unique needs. This level of customization sets {Company Name} apart from its competitors, as it demonstrates the company's dedication to delivering tailored solutions that exceed customer expectations.In addition to its product offerings, {Company Name} is also committed to providing exceptional customer service and support. The company's team of knowledgeable professionals is readily available to assist customers with any inquiries they may have, ensuring a seamless and positive experience throughout the purchasing process. Moreover, {Company Name} prides itself on its efficient order fulfillment and quick delivery times, allowing customers to receive the wire sleeving they need in a timely manner.Looking ahead, {Company Name} remains dedicated to driving innovation in the wire sleeving industry, continuously exploring new materials and manufacturing techniques to enhance the performance and reliability of its products. The company's commitment to quality and customer satisfaction serves as a driving force behind its success, as it continues to position itself as a trusted partner for businesses and individuals in need of durable cable protection solutions.In conclusion, {Company Name} has established itself as a leading provider of braided nylon wire sleeving, offering a range of high-quality products that deliver exceptional protection and durability for cables. With a focus on innovation, customization, and outstanding customer service, the company is well-positioned to meet the evolving needs of its customers and drive positive change in the wire sleeving industry. Whether it's for automotive, aerospace, telecommunications, or other applications, {Company Name}'s braided nylon wire sleeving is the go-to solution for reliable cable protection.

Durable and Protective High Temperature Braided Sleeving for Various Applications

High Temp Braided Sleeving: The Ultimate Solution for Extreme Temperature ChallengesIn today's business landscape, efficiency, effectiveness, and reliability have become crucial factors for achieving sustainable growth and success. Among a wide range of industries, this is especially true for the aerospace, automotive, electrical, and military sectors where environmental factors, such as high temperatures, can cause significant damage to components and systems.High Temp Braided Sleeving is a game-changer, providing an unmatched solution for such extreme temperature challenges. It is an innovative, flexible, and durable solution that can help protect sensitive components and cables from exposure to high temperatures, chemicals, abrasion, and other environmental factors.What is High Temp Braided Sleeving?High Temp Braided Sleeving is a flexible, lightweight, and highly durable material that can protect cables and wiring from harmful environmental factors. It is made from a variety of materials, including fiberglass, Kevlar, nylon, and other advanced materials that make it resistant to fire, chemicals, and abrasion.The braided wires are treated with an insulating coating that enhances its ability to withstand severe conditions. The material can operate from -70°C to +260°C and can easily expand and contract according to the movement of the components.How Can High Temp Braided Sleeving Help Industries?High Temp Braided Sleeving provides a perfect solution for industries where exposure to harsh environmental factors can cause significant damage to equipment, machinery, and systems. Here are some of the industries that can leverage the benefits of High Temp Braided Sleeving.1. Aerospace IndustryIn the aerospace industry, High Temp Braided Sleeving can protect delicate sensors, cables, and wiring in harsh environmental conditions, such as high temperatures, humidity, and pressure. It can resist fire, chemicals, and abrasion and keep the components safe from any damage.2. Automotive IndustryIn the automotive industry, High Temp Braided Sleeving can protect the cables and wiring in environments where high temperature and vibration can cause them to wear out quickly. The material can withstand the high temperatures of the engine bay and prevent damage to critical components, such as the wiring harnesses.3. Electrical IndustryIn the electrical industry, High Temp Braided Sleeving can protect wires and cables in harsh environments where temperatures, UV radiations, and chemicals can cause damage. It can protect the cables and wiring from abrasion, dust, and other unwanted particles.4. Military IndustryIn the military industry, High Temp Braided Sleeving can protect electronic equipment from harsh environments where military vehicles and aircraft operate. It can resist high temperatures and harsh chemicals, making it the perfect material to protect the cables and wires from damage.Why Choose Our High Temp Braided Sleeving?The High Temp Braided Sleeving offered by our company is made from the highest quality materials, making it one of the most durable and reliable products on the market. Our braided sleeves have various beneficial features that make them suitable for a wide range of applications, including:1. Temperature Resistance: With its superior heat resistance, our High Temp Braided Sleeving can operate in environments up to 260°C.2. Chemical Resistance: Our braided sleeves are highly resistant to chemicals, solvents, and oils, making them an ideal material for use in harsh environments.3. Durable: Our High Temp Braided Sleeving is highly durable and can withstand extensive wear and tear that can damage other materials.4. Flexible: Our braided sleeves are highly flexible and can easily bend and move according to the components' motion, making them perfect for use in tight spaces.5. Easy to Install: Our braided sleeves are easy to install and can be used for different applications, including protecting cables, wiring, hoses, tubing, and other components.ConclusionHigh Temp Braided Sleeving is an ideal solution for many industries facing extreme temperature challenges. It provides ultimate protection to delicate components, cables, and wiring from harsh environmental factors, such as high temperatures, chemicals, and abrasion. Our company offers the highest quality braided sleeves made from the most durable and reliable materials. By leveraging our High Temp Braided Sleeving, industries can enhance efficiency, effectiveness, and reliability and achieve sustainable growth and success.

Braided Cable Sheath: Enhancing Protection and Durability

Title: Innovative Braided Cable Sheath Enhances Durability and FunctionalityIntroduction:In today's fast-paced and interconnected world, cables have become an integral part of our lives, facilitating seamless connectivity and powering a wide range of devices. As technology evolves, there is a growing need for cables that can withstand the demands of daily use, offering enhanced durability without compromising on functionality. This is where the innovative Braided Cable Sheath, developed by an industry-leading company, comes into play. With its unique design and advanced features, this cable sheath is set to revolutionize the market.Body:1. Overview of Braided Cable Sheath:The Braided Cable Sheath, a creation of a renowned company, is engineered to provide a robust and long-lasting solution for cable protection. This innovative sheath adopts a braided design, ensuring superior flexibility and durability compared to traditional cable housing. By combining high-quality materials with cutting-edge manufacturing techniques, this cable sheath delivers exceptional performance in challenging environments.2. Unmatched Durability:One of the standout features of the Braided Cable Sheath is its remarkable durability. The blend of high-tensile strength materials and a tightly woven braided pattern creates a protective barrier that safeguards cables against abrasion, bending, and impacts. This means that users can rely on these cables even in high-stress situations, both indoors and outdoors, ensuring uninterrupted connectivity.3. Enhanced Functionality:Beyond its durability, the Braided Cable Sheath offers several features that enhance functionality and user experience. With its remarkable flexibility, the sheath allows for easy cable management, minimizing tangles and knots. Moreover, the braided design dissipates heat efficiently, preventing overheating issues often associated with prolonged use of cables. This not only improves the lifespan of the cables but also provides a safe and reliable connection for users.4. Versatility:The Braided Cable Sheath is designed to cater to a wide range of applications. Its adaptability allows it to be used in various industries, including consumer electronics, telecommunications, automotive, and aerospace. Whether it is used for charging cables, data transfer cables, or audio-video connections, this versatile sheath ensures optimal performance and longevity.5. Industry-leading Standards:The company behind the Braided Cable Sheath is well-known for its commitment to adherence to industry standards. The sheath undergoes rigorous testing to meet and exceed the highest quality requirements, ensuring that each product is reliable, safe, and long-lasting. Additionally, with a dedicated team of experts and engineers, the company implements continuous research and development efforts to stay ahead of evolving technological needs.6. Eco-conscious Manufacturing:In an era of environmental awareness, it is encouraging to note that the Braided Cable Sheath is manufactured with sustainability in mind. The company employs eco-friendly practices throughout the production process, minimizing waste generation and utilizing recyclable materials. By choosing these innovative cable sheaths, users can contribute to a greener future.Conclusion:The introduction of the Braided Cable Sheath marks a significant advancement in cable protection technology. With its unbeatable durability, enhanced functionality, versatility, and adherence to industry standards, this innovative sheath is set to become the go-to choice for various sectors. As technology continues to evolve, the Braided Cable Sheath ensures that cables keep pace with the demands of modern connectivity while offering a reliable and long-lasting solution.

Enhancing Filtration Membranes: A Guide to Reinforcement Techniques

[Company Name], a global leader in membrane technology and filtration solutions, has recently announced a breakthrough in Filtration Membrane Reinforcement. This new technology promises to revolutionize the filtration industry by increasing the durability and efficiency of filtration membranes.Filtration membranes are widely used in a variety of industries, including water treatment, pharmaceuticals, and food and beverage production. These membranes are designed to separate solids from liquids and are critical for ensuring the purity and quality of the final product. However, one of the challenges with existing filtration membranes is their vulnerability to damage and fouling, which can result in decreased performance and increased maintenance costs.The new Filtration Membrane Reinforcement technology developed by [Company Name] addresses this challenge by enhancing the strength and durability of filtration membranes. By leveraging advanced materials and manufacturing techniques, the company has been able to significantly improve the resistance of membranes to fouling, chemical degradation, and mechanical stress. This means that filtration systems equipped with this new technology will be able to operate for longer periods without the need for frequent maintenance and replacement of membranes.In addition to the improved durability, the Filtration Membrane Reinforcement technology also offers enhanced filtration efficiency. The reinforced membranes are designed to provide a higher flux rate, allowing for faster and more effective filtration. This will not only result in cost savings for companies using these membranes but also contribute to a more sustainable and environmentally friendly filtration process.[Company Name] has a long-standing reputation for innovation and excellence in the field of membrane technology. With over 30 years of experience, the company has established itself as a trusted partner for businesses looking to improve their filtration processes. The introduction of the Filtration Membrane Reinforcement technology further solidifies [Company Name]'s position as a leading provider of advanced filtration solutions.The company's commitment to research and development has been a driving force behind its success. With a dedicated team of scientists, engineers, and industry experts, [Company Name] continues to push the boundaries of what is possible in the world of filtration. The development of the Filtration Membrane Reinforcement technology is a testament to the company's relentless pursuit of innovation and its unwavering dedication to meeting the evolving needs of its customers.The potential impact of the Filtration Membrane Reinforcement technology extends beyond just the filtration industry. As businesses across various sectors strive to improve their sustainability and environmental performance, the ability to enhance the durability and efficiency of filtration membranes will be crucial. By reducing the frequency of membrane replacements and improving overall filtration performance, companies using this new technology can minimize their environmental footprint and improve their operational efficiency.The unveiling of the Filtration Membrane Reinforcement technology has generated significant excitement within the industry, with many businesses expressing interest in integrating this innovation into their operations. As [Company Name] prepares to bring this technology to market, the company is poised to redefine the standards for filtration membranes and set a new benchmark for durability and performance.In conclusion, the introduction of the Filtration Membrane Reinforcement technology by [Company Name] represents a major milestone in the evolution of filtration solutions. This breakthrough innovation promises to deliver significant benefits to businesses across various industries, from improved operational efficiency to enhanced sustainability. As [Company Name] continues to lead the way in membrane technology and filtration solutions, the future of filtration is looking brighter than ever.

High-Quality Expandable Braided Sleeving for Various Applications

Introducing the Latest Innovation in Cable Management: Nylon Expandable Braided SleevingIn today's rapidly evolving technological landscape, the demand for efficient and reliable cable management solutions has never been higher. As the market continues to expand, companies are constantly seeking products that can provide effective protection and organization for their cables. This is why we are proud to introduce our latest innovation in cable management: Nylon Expandable Braided Sleeving.Our Nylon Expandable Braided Sleeving is a versatile and durable solution that is designed to meet the growing demands of modern cable management. With a focus on flexibility and expandability, this sleeving is ideal for a wide range of applications, from automotive and aerospace to industrial and home electronics.One of the key features of our Nylon Expandable Braided Sleeving is its unique construction, which allows for easy installation and removal. This makes it an ideal choice for applications where frequent access to cables is necessary, as it can be easily expanded to accommodate additional wires and then retracted for a secure fit.In addition to its expandability, our Nylon Expandable Braided Sleeving is also highly resistant to abrasion, making it ideal for use in harsh environments where cables are exposed to a high degree of wear and tear. This makes it a cost-effective solution for industries such as manufacturing and construction, where cable protection is essential for maintaining productivity and safety.Furthermore, our Nylon Expandable Braided Sleeving is designed to provide excellent thermal insulation, making it suitable for use in applications where temperature control is critical. Whether it's in an automotive engine compartment or a server room, this sleeving can help to safeguard cables from extreme temperatures, prolonging their lifespan and reducing the risk of damage.Another important aspect of our Nylon Expandable Braided Sleeving is its ability to provide electromagnetic shielding, which is crucial for preventing signal interference in sensitive electronic equipment. This makes it an ideal choice for use in the telecommunications and IT industries, as well as in medical devices where reliable signal transmission is essential.At [Company Name], we take pride in delivering innovative solutions that meet the evolving needs of our customers. Our Nylon Expandable Braided Sleeving is no exception, as it represents our ongoing commitment to providing high-quality products that offer superior performance and reliability.With a focus on durability, flexibility, and versatility, our Nylon Expandable Braided Sleeving is setting a new standard in cable management. Whether it's for large-scale industrial applications or small-scale home electronics, this sleeving is poised to make a significant impact on the market.As we continue to see advancements in technology and a growing emphasis on connectivity, the demand for effective cable management solutions will only continue to rise. With our Nylon Expandable Braided Sleeving, we are proud to offer a solution that not only meets this demand but also sets a new benchmark for performance and durability.In conclusion, we are excited to introduce our Nylon Expandable Braided Sleeving as the latest innovation in cable management. With its unique combination of expandability, durability, and versatility, this sleeving is well-positioned to meet the evolving needs of today's fast-paced and interconnected world. Whether it's for commercial, industrial, or personal use, our sleeving is designed to provide the ultimate protection and organization for cables of all types. We look forward to the positive impact that our Nylon Expandable Braided Sleeving will have on the market and the various industries it serves.

New Innovation: Self-Closing Sleeve for Power Cables Improves Safety and Efficiency

article:Self-Closing Power Cable Sleeves: A Breakthrough in Cable Management TechnologyCable management has been an age-old problem among individuals and businesses alike. With the increasing number of devices we use on a day-to-day basis, the demand for organizing cables and wires has become more important than ever. Cables can easily tangle, tangle, or can become a potential hazard for those working in close proximity. Thankfully, there is a solution in the form of self-closing power cable sleeves.A leading manufacturer in cable management, has created a breakthrough product in the form of a self-closing power cable sleeve. This unique product has been designed to provide a simple and safe solution to tangle and clutter-prone wires and cables. The cable sleeve is made from high-quality materials that are both durable and resistant to wear and tear.The self-closing power cable sleeve features an innovative design that allows users to easily add or remove cables as needed. The sleeve is made from a flexible material that expands and contracts to accommodate different-sized cables, making it a versatile product to use.Another key feature of the self-closing power cable sleeve is its safety feature. The sleeve is designed to fully encase the cables, protecting them from potential hazards such as moisture, dust, or abrasions. The cable sleeve's self-closing design ensures that cables are kept away from sharp edges, preventing any possible damages.Installation of the self-closing power cable sleeve is a breeze. The sleeve can be easily installed by sliding it over the cables, and it will stay in place, preventing the cables from being pulled out. After installation, the sleeve can be easily removed to access the cables or add new ones.The company is committed to providing high-quality cable management solutions to its customers. They have invested a significant amount of time and funds into research and development to create innovative products that can meet the ever-changing needs of users. Their self-closing power cable sleeve is no exception, as it is designed to make cable management easier, safer, and more efficient.The self-closing power cable sleeve is ideal for use in a variety of settings. It is ideal for use in homes, offices, and workplaces, where cables need to be organized and kept away from potential hazards. The sleeve can be used on different-sized cables, making it a product that can be used across a variety of devices.Overall, the self-closing power cable sleeve is a breakthrough product that represents the future of cable management technology. The product's innovative design, safety features, ease of installation, and versatility make it a must-have for anyone who values organized cables and a clutter-free workspace. The company is proud to provide customers with a product that can make their lives simpler and safer.

Advanced Heat Management Textile: A Groundbreaking Solution for Temperature Regulation

Heat Management Textile: Revolutionizing the World of ThermoregulationIn a world where temperature extremes are becoming increasingly common, the need for textiles that can effectively manage heat has never been greater. Addressing this crucial aspect of our daily lives, {company name}, a leading innovator in the textile industry, has unveiled their groundbreaking Heat Management Textile, which promises to revolutionize the world of thermoregulation.Traditionally, textiles have primarily focused on insulation to keep individuals warm in cold weather. While this has undoubtedly been crucial in ensuring comfort, the ability to effectively manage heat in varying environments has remained a challenge. Recognizing this unmet need, {company name} embarked on a tireless journey to develop a textile solution that can adaptively respond to temperatures, keeping the wearer cool or warm depending on the conditions.The result of years of research and development, {company name}'s Heat Management Textile combines cutting-edge technology, innovative design, and sustainable materials to provide an unparalleled thermoregulation experience. Unlike traditional textiles, which act as mere barriers between the wearer and the environment, this groundbreaking textile actively responds to changes in temperature, ensuring optimal comfort at all times.At the heart of this textile is the integration of advanced phase change materials (PCM) and intelligent sensors. The PCM embedded within the textile absorbs, stores, and releases heat as necessary, thereby maintaining a balanced temperature around the wearer. This unique feature allows the textile to adapt to both hot and cold conditions, making it highly versatile and suitable for a wide range of applications.In addition to PCM, the Heat Management Textile incorporates intelligent sensors that constantly monitor the surrounding temperature. These sensors, intricately woven into the fabric, provide real-time feedback to the PCM layer, enabling rapid adjustments and precise temperature control. This dynamic system ensures the wearer remains comfortable, regardless of external weather conditions.To further enhance its functionality, {company name} has also incorporated moisture-wicking and breathability properties into the Heat Management Textile. This ensures that excess moisture, such as sweat, is efficiently drawn away from the body, allowing for quick evaporation and a dry, comfortable feel. By efficiently managing moisture, the textile not only contributes to temperature regulation but also prevents unpleasant odors and the growth of bacteria.As an environmentally conscious company, {company name} has not compromised on sustainability in the development of the Heat Management Textile. The textile utilizes eco-friendly materials sourced from responsibly managed suppliers. Additionally, the production process incorporates energy-efficient manufacturing techniques, minimizing carbon emissions and reducing the overall environmental impact.Furthermore, the longevity of the Heat Management Textile is a testament to its durability, ensuring that it can withstand frequent use and repeated washing without compromising its performance. This durability not only extends the lifespan of the product but also reduces the need for constant replacement, thus making it a sustainable choice for consumers.With its exceptional functionality and sustainability, the Heat Management Textile has sparked immense interest across various industries. From sports apparel to outdoor gear, medical applications to automotive interiors, the possibilities for its implementation are vast. This innovative textile has the potential to redefine our daily lives, providing unparalleled comfort and adaptability in the face of changing climates.{Company name}'s Heat Management Textile represents a monumental leap forward in the field of thermoregulation. Its integration of advanced phase change materials, intelligent sensors, and sustainable practices sets a new standard for textile innovation. As we navigate a world of temperature extremes, this revolutionary textile promises to keep us comfortable, no matter the weather.

A New Expandable Sleeve Technology Promises More Efficient Cable Management

Emi: The Pioneering Expandable Sleeve Revolutionizing Industrial PackagingIn the fast-paced world of industrial packaging, companies are constantly on the lookout for innovative solutions that can increase efficiency, reduce costs, and improve overall productivity. Emi, a trailblazer in the industry, has set itself apart with its groundbreaking expandable sleeve technology. With its superior performance and versatility, Emi's expandable sleeves have become an indispensable tool for various sectors, from automotive to food and beverage.Emi's expandable sleeves are designed to accommodate a wide range of products, providing a secure and customized fit that ensures maximum protection during transportation and storage. With the ability to seamlessly expand or contract, these sleeves can adapt to the dimensions of different items, eliminating the need for multiple packaging solutions. This not only saves time but also reduces material waste, making it an environmentally-friendly choice for businesses.One of the key advantages of Emi's expandable sleeves lies in their durability. Constructed using high-quality materials and advanced manufacturing techniques, these sleeves are built to withstand the rigors of various industry settings. Whether it's exposure to extreme temperatures or rough handling during transit, Emi's expandable sleeves provide reliable protection, keeping products intact and damage-free.Moreover, Emi's expandable sleeves offer excellent flexibility, allowing them to conform to irregularly shaped items effortlessly. This versatility is particularly beneficial for companies with unique packaging requirements. Whether it's a delicate electronic component or an odd-shaped automotive part, Emi's expandable sleeves provide a snug fit that eliminates the risk of damage during handling and transportation.In addition to their protective qualities, Emi's expandable sleeves boast excellent product visibility. Their transparency allows businesses to easily identify and inspect packaged items without the need for unpacking, reducing the chances of errors and optimizing operational efficiency. This feature is especially valuable in industries where traceability and quality control are of utmost importance.Emi is committed to not only providing superior packaging solutions but also fostering sustainability. The company recognizes the importance of eco-friendly practices in today's world and ensures that its expandable sleeves are recyclable and made from environmentally conscious materials. By championing sustainable packaging, Emi is aiding businesses in their efforts to reduce their carbon footprint and embrace greener alternatives.With a global mindset, Emi has successfully collaborated with companies across continents, delivering its innovative expandable sleeves to clients worldwide. This has established the company's reputation as a trusted partner when it comes to industrial packaging solutions. By prioritizing customer satisfaction and continuously improving its products, Emi has earned the loyalty of a diverse range of industries, including electronics, pharmaceuticals, and consumer goods.Emi's commitment to innovation and customer-focused solutions has led to numerous accolades and recognition within the industry. Notably, the company was recently awarded the prestigious Packaging Innovation Award for its expandable sleeve technology. This recognition underscores Emi's dedication to pushing the boundaries of industrial packaging and providing game-changing solutions for its clients.As the global industrial packaging market continues to expand, Emi remains at the forefront, spearheading new advancements and setting industry standards. With its pioneering expandable sleeves, the company is revolutionizing the way products are protected and transported. By offering durability, flexibility, and sustainability, Emi's expandable sleeves have become a cornerstone of efficient packaging solutions across various industries, confirming the company's position as a true industry leader.