Durable and Protective High Temperature Braided Sleeving for Various Applications

By:Admin

In today's business landscape, efficiency, effectiveness, and reliability have become crucial factors for achieving sustainable growth and success. Among a wide range of industries, this is especially true for the aerospace, automotive, electrical, and military sectors where environmental factors, such as high temperatures, can cause significant damage to components and systems.

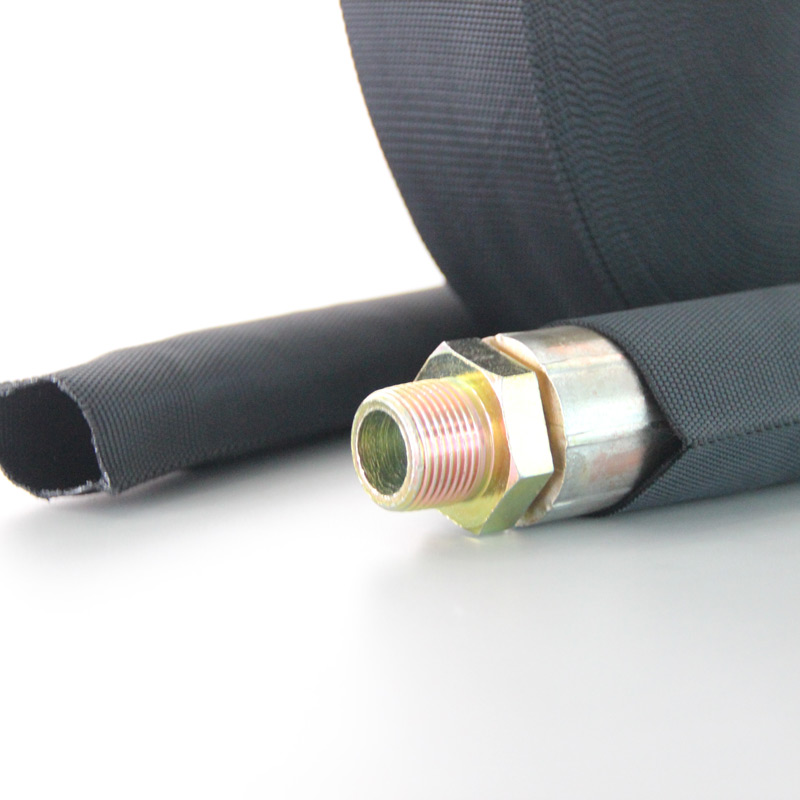

High Temp Braided Sleeving is a game-changer, providing an unmatched solution for such extreme temperature challenges. It is an innovative, flexible, and durable solution that can help protect sensitive components and cables from exposure to high temperatures, chemicals, abrasion, and other environmental factors.

What is High Temp Braided Sleeving?

High Temp Braided Sleeving is a flexible, lightweight, and highly durable material that can protect cables and wiring from harmful environmental factors. It is made from a variety of materials, including fiberglass, Kevlar, nylon, and other advanced materials that make it resistant to fire, chemicals, and abrasion.

The braided wires are treated with an insulating coating that enhances its ability to withstand severe conditions. The material can operate from -70°C to +260°C and can easily expand and contract according to the movement of the components.

How Can High Temp Braided Sleeving Help Industries?

High Temp Braided Sleeving provides a perfect solution for industries where exposure to harsh environmental factors can cause significant damage to equipment, machinery, and systems. Here are some of the industries that can leverage the benefits of High Temp Braided Sleeving.

1. Aerospace Industry

In the aerospace industry, High Temp Braided Sleeving can protect delicate sensors, cables, and wiring in harsh environmental conditions, such as high temperatures, humidity, and pressure. It can resist fire, chemicals, and abrasion and keep the components safe from any damage.

2. Automotive Industry

In the automotive industry, High Temp Braided Sleeving can protect the cables and wiring in environments where high temperature and vibration can cause them to wear out quickly. The material can withstand the high temperatures of the engine bay and prevent damage to critical components, such as the wiring harnesses.

3. Electrical Industry

In the electrical industry, High Temp Braided Sleeving can protect wires and cables in harsh environments where temperatures, UV radiations, and chemicals can cause damage. It can protect the cables and wiring from abrasion, dust, and other unwanted particles.

4. Military Industry

In the military industry, High Temp Braided Sleeving can protect electronic equipment from harsh environments where military vehicles and aircraft operate. It can resist high temperatures and harsh chemicals, making it the perfect material to protect the cables and wires from damage.

Why Choose Our High Temp Braided Sleeving?

The High Temp Braided Sleeving offered by our company is made from the highest quality materials, making it one of the most durable and reliable products on the market. Our braided sleeves have various beneficial features that make them suitable for a wide range of applications, including:

1. Temperature Resistance: With its superior heat resistance, our High Temp Braided Sleeving can operate in environments up to 260°C.

2. Chemical Resistance: Our braided sleeves are highly resistant to chemicals, solvents, and oils, making them an ideal material for use in harsh environments.

3. Durable: Our High Temp Braided Sleeving is highly durable and can withstand extensive wear and tear that can damage other materials.

4. Flexible: Our braided sleeves are highly flexible and can easily bend and move according to the components' motion, making them perfect for use in tight spaces.

5. Easy to Install: Our braided sleeves are easy to install and can be used for different applications, including protecting cables, wiring, hoses, tubing, and other components.

Conclusion

High Temp Braided Sleeving is an ideal solution for many industries facing extreme temperature challenges. It provides ultimate protection to delicate components, cables, and wiring from harsh environmental factors, such as high temperatures, chemicals, and abrasion. Our company offers the highest quality braided sleeves made from the most durable and reliable materials. By leveraging our High Temp Braided Sleeving, industries can enhance efficiency, effectiveness, and reliability and achieve sustainable growth and success.

Company News & Blog

New Protective Sleeve Perfectly Shields Devices from Damage

Title: Innovative Protective Sleeve Offers Unparalleled Protection - EmiTech Leading the WayIntroduction:In today's rapidly evolving technological landscape, the need to safeguard electronic devices against electromagnetic interference (EMI) has become more crucial than ever. EmiTech, a pioneering company at the forefront of advanced electromagnetic shielding solutions, has recently unveiled its revolutionary protective sleeve. This cutting-edge product, known as the Emi Protecting Sleeve, has garnered considerable attention for its ability to provide unparalleled protection to a wide range of electronic devices. In this article, we will explore the features and benefits of EmiTech's innovative protective sleeve, shedding light on the technological breakthrough that is revolutionizing the industry.Unmatched Shielding Capabilities:With the increasing ubiquity of wireless technologies and electronic devices, the risk of EMI compromising their performance has become a significant concern for both consumers and manufacturers. However, EmiTech's Protecting Sleeve has emerged as a game-changer in the field of EMI protection. Leveraging advanced materials and state-of-the-art design elements, the sleeve provides unmatched shielding capabilities to safeguard electronic devices against EMI, ensuring their optimal functioning.Cutting-edge Design:EmiTech's Protecting Sleeve is characterized by its innovative design, which combines functionality with aesthetic appeal. Crafted with precision, the sleeve features a seamless fusion of lightweight, durable materials that do not compromise on style. This design ensures that electronic devices remain protected without sacrificing their sleek appearance. Additionally, the sleeve's flexible yet resilient composition enables it to adapt to various device sizes, offering universal compatibility for a wide array of gadgets.Comprehensive EMI Protection:The Emi Protecting Sleeve offers comprehensive EMI protection, safeguarding devices from a broad range of electromagnetic interferences. Whether it is protecting smartphones, tablets, laptops, or even medical equipment, this innovative sleeve is engineered to shield against potentially disruptive electromagnetic waves. By implementing cutting-edge technology, EmiTech has developed a product that provides a robust defense against EMI, minimizing signal disruptions and optimizing device performance.Durability and Practicality:EmiTech's Protecting Sleeve not only delivers unmatched EMI protection but also prioritizes durability and practicality. The sleeve is built to withstand daily wear and tear, featuring resilient construction that can withstand various environmental conditions. Moreover, the sleeve's practical design ensures ease of use, allowing users to seamlessly access their device's functions, including charging, cameras, and other ports, without the need for removing the sleeve. This convenience makes the protective sleeve an ideal solution for those seeking a balance between functionality and device protection.EmiTech's Commitment to Excellence:EmiTech, the company behind the revolutionary Protecting Sleeve, has set a benchmark in the industry with its unwavering commitment to excellence. With a team of highly skilled engineers and experts, EmiTech continuously strives to push the boundaries of technological advancements by conducting rigorous research and development. The Emi Protecting Sleeve serves as a testament to the company's commitment to providing reliable and innovative EMI protection solutions.Conclusion:In an era dominated by electronic devices, the Emi Protecting Sleeve stands out as a groundbreaking solution for protecting these gadgets against electromagnetic interference. EmiTech's commitment to excellence and their cutting-edge design have resulted in a protective sleeve that not only shields against EMI but also offers durability and practicality. As the global demand for reliable EMI protection continues to rise, EmiTech's Protecting Sleeve is poised to become an industry standard. By combining state-of-the-art technology with a commitment to innovation, EmiTech proves its place as a leader in the field of electromagnetic shielding solutions.

How to Use Stainless Steel Wire Sleeve for Cable Protection

Title: High-Quality Stainless Steel Wire Sleeve Revolutionizes Industrial ApplicationsIntroduction:In today's fast-paced industrial world, where efficiency and durability are paramount, one company stands out with its revolutionary Stainless Steel Wire Sleeve. Renowned for its top-notch quality and unmatched performance, this innovative product has gained significant attention from various industries worldwide. In this article, we will delve into the exceptional features and applications of the Stainless Steel Wire Sleeve, along with the transformative impact it has on industrial operations.Product Overview:The Stainless Steel Wire Sleeve, developed by a leading manufacturer, is a cutting-edge solution engineered to provide exceptional wire management, protection, and organization. Crafted from high-grade stainless steel, this versatile product is known for its remarkable strength, durability, and resistance to corrosion, extreme temperatures, and chemicals. Furthermore, its flexibility ensures a hassle-free installation process.Unmatched Features:One of the standout features of the Stainless Steel Wire Sleeve is its ability to offer superior protection for electrical, data, and communication wires. The robust stainless steel construction shields cables from external hazards, such as abrasions, UV radiation, and electromagnetic interference. This protection extends the lifespan of wires and prevents costly damage, ensuring continuous and uninterrupted operations.The wire sleeve's exceptional flexibility enables smooth and effortless routing in diverse environments, saving time and effort during installation. Its unique design incorporates an open structure, allowing easy access for maintenance and future expansion. Additionally, the Stainless Steel Wire Sleeve offers exceptional mechanical stability, securing wires in place and minimizing vibration-related issues.Applications across Industries:The unparalleled quality and versatility of the Stainless Steel Wire Sleeve make it an ideal choice for a wide range of industries. In the automotive sector, this product efficiently manages the complex wiring systems found in vehicles, ensuring durability and safety. Similarly, the aerospace industry benefits from the wire sleeve's ability to handle challenging conditions, safeguarding electrical systems in aircraft.In the construction and infrastructure sector, the Stainless Steel Wire Sleeve provides reliable wire protection against harsh weather conditions and accidental damage. This product is also highly sought-after in the energy and telecommunications industries. It supports efficient cable management in power plants, substations, and data centers, allowing seamless transmission of electricity and data.Moreover, the Stainless Steel Wire Sleeve finds application in the medical field, where precision and durability are of utmost importance. It protects delicate medical device wiring, ensuring patients' safety during critical procedures. The wire sleeve has also been widely utilized in manufacturing processes to streamline industrial automation, enabling efficient conveyance of electrical signals and data.Sustainability and Compliance:The manufacturer of the Stainless Steel Wire Sleeve is committed to environmental responsibility. The product is crafted using sustainable manufacturing practices, minimizing waste and resource consumption. Additionally, the wire sleeve meets several international standards and certifications, such as RoHS and REACH, ensuring compliance with stringent regulatory requirements.Conclusion:The Stainless Steel Wire Sleeve has emerged as a game-changer in the industrial sector. With its exceptional strength, durability, and protection capabilities, this innovative product has transformed wire management practices across a wide range of industries. Its versatility and reliability make it an indispensable solution for various applications, allowing businesses to optimize efficiency, minimize downtime, and maximize overall productivity. As industries continue to evolve, the Stainless Steel Wire Sleeve remains a beacon of excellence, promising a future of superior wire management and protection.

Everything You Need to Know About the Versatile Carbon Fiber Braid

Carbon Fiber Braid Revolutionizes Manufacturing Processes in Various Industries[Company Name], a leader in innovative composite materials, is set to revolutionize manufacturing processes across industries with its latest product, Carbon Fiber Braid. The company's commitment to pushing the boundaries of composite materials and their applications has led to the development of a game-changing technology that promises increased strength, durability, and versatility. This breakthrough innovation has caught the attention of industry experts, who believe it will reshape manufacturing in fields as diverse as automotive, aerospace, and construction.Carbon fiber, renowned for its exceptional strength-to-weight ratio, has been widely used in industries where lightweight and durable materials are crucial. However, the conventional manufacturing methods for carbon fiber products can be labor-intensive and time-consuming. This is where [Company Name]'s Carbon Fiber Braid sets itself apart. By utilizing advanced braiding technology, the company has successfully optimized the manufacturing process, making it faster, more cost-effective, and highly scalable.The Carbon Fiber Braid consists of multiple carbon fiber tows intertwined in an intricate 3D pattern, resulting in a braided structure with remarkable mechanical properties. This unique design enhances the material's resistance to impact, fatigue, and stress, making it ideal for applications that require high performance and reliability. Furthermore, the braid configuration allows for easy customization, enabling manufacturers to tailor the product according to their specific requirements. This versatile feature makes Carbon Fiber Braid adaptable to a wide range of applications.In the automotive industry, Carbon Fiber Braid is set to revolutionize vehicle design and manufacturing. With its superior strength and lightweight characteristics, it offers significant potential for reducing vehicle weight, resulting in improved fuel efficiency and lower emissions. Additionally, its increased impact resistance enhances passenger safety without compromising performance. Automobile manufacturers can now leverage this cutting-edge technology to create lighter, safer, and more fuel-efficient vehicles.Similarly, the aerospace industry stands to benefit immensely from the introduction of Carbon Fiber Braid. By replacing traditional metal components with this innovative material, aircraft manufacturers can reduce the weight of their aircraft, resulting in reduced fuel consumption and increased payload capacity. The enhanced mechanical properties of Carbon Fiber Braid make it an ideal choice for critical components such as wing structures, landing systems, and rotor blades. This breakthrough technology promises to revolutionize the aerospace industry by enabling the production of more efficient and eco-friendly aircraft.Construction is yet another sector that can leverage the advantages of Carbon Fiber Braid. The material's unmatched strength ensures the integrity and longevity of buildings, bridges, and infrastructure projects. By incorporating Carbon Fiber Braid into construction processes, builders can significantly reduce the weight of structures while maintaining structural stability. This not only increases construction efficiency but also reduces transportation costs and environmental impact. From strengthening concrete structures to reinforcing seismic zones, Carbon Fiber Braid ushers in a new era of sustainable and resilient construction practices.[Company Name] has already collaborated with several prominent industry players to conduct extensive testing and validation of Carbon Fiber Braid. Initial results have been overwhelmingly positive, further solidifying its potential to revolutionize various manufacturing processes. The company's commitment to research and development ensures that this breakthrough technology will continue to evolve, bringing about untapped possibilities for numerous industries.In conclusion, Carbon Fiber Braid represents a game-changing innovation in the field of composite materials. By utilizing advanced braiding technology, [Company Name] has optimized the manufacturing process, resulting in a versatile and high-performance material. With its exceptional mechanical properties, Carbon Fiber Braid promises to revolutionize manufacturing processes in industries such as automotive, aerospace, and construction. The future is bright for Carbon Fiber Braid and the exciting possibilities it offers for creating more efficient, sustainable, and resilient products.

Top-Rated Expandable Sleeving for Pets Revealed in Latest News

Title: Innovative Pet Expandable Sleeving Revolutionizes Cable ManagementIntroduction:In today's advanced technological era, the demand for organized and efficient cable management solutions has never been higher. In response to this growing need, an innovative product known as Pet Expandable Sleeving has been introduced by a leading company, revolutionizing cable management practices in a wide range of industries.Body:1. Understanding the importance of cable management:Efficient cable management plays a crucial role in various industries, including electronics, automotive, aerospace, and telecommunications. It ensures optimal performance, minimizes the risk of damage or accidents, and improves overall aesthetics. However, traditional cable management solutions have often been tedious to install, lacked flexibility, and failed to meet evolving needs.2. Introducing Pet Expandable Sleeving:Pet Expandable Sleeving, developed by an industry-renowned manufacturer, offers a lightweight, flexible, and highly effective cable management solution. Made from a high-quality polyester material, it is designed to expand and contract, providing a customizable and snug fit around cables.3. Features and benefits of Pet Expandable Sleeving:- Durability: The Pet Expandable Sleeving is resistant to abrasion, chemicals, and high temperatures, ensuring long-term reliability.- Easy installation: With its expandable nature and unique self-wrapping feature, the sleeving can be effortlessly installed, eliminating the need for extensive labor or specialized tools.- Cable protection: By securing cables within the sleeving, Pet Expandable Sleeving prevents tangling, fraying, and damage caused by external factors.- Aesthetically appealing: The sleek, clean, and organized appearance achieved through the use of Pet Expandable Sleeving enhances the overall visual appeal of electronic devices, vehicles, and other applications.- Flexibility: The expandable sleeving conforms to various cable shapes and sizes, allowing for easy customization and adaptability.- Variety of applications: Pet Expandable Sleeving finds applications across numerous industries, including electronics, automotive, marine, and telecommunications, due to its versatile nature.4. Role of Pet Expandable Sleeving in the automotive industry:In the automotive sector, cable management is essential for efficient operation and safety. Pet Expandable Sleeving has emerged as a game-changer, providing several advantages for automotive wiring systems, including resistance to oil, chemicals, and vibrations. It ensures a secure and protected environment for the intricate electrical systems present in modern vehicles.5. Use of Pet Expandable Sleeving in the electronics industry:The electronics industry demands precise cable management to maintain optimal system efficiency and prevent signal interference. Pet Expandable Sleeving offers an ideal solution with its excellent electromagnetic interference shielding properties. By minimizing electromagnetic emissions, it helps maintain signal integrity, ensuring reliable performance in complex electronic systems.6. Environmental consideration:Pet Expandable Sleeving is manufactured from 100% recyclable polyester material, making it an environmentally friendly choice. The sleeving's long-lasting durability reduces waste, as it can be reused or recycled at the end of its lifecycle.Conclusion:Pet Expandable Sleeving has emerged as a ground-breaking solution for effective cable management in numerous industries. Its durability, ease of installation, and flexibility make it an invaluable asset for organizing and protecting cables, leading to improved system performance and visual appeal. As the demand for efficient cable management grows, Pet Expandable Sleeving continues to pave the way for innovative solutions in the field.

Discover the Benefits of Polyester Braided Sleeving for Your Needs

Polyester Braided Sleeving Provides Superior Protection for Electrical WiresIn the digital age, the need for reliable and efficient electrical wiring solutions is more important than ever. Businesses and individuals rely on secure and stable power transmission to keep their operations running smoothly. This is where polyester braided sleeving comes in.Polyester braided sleeving is a tubular sleeve of woven polyester fibers that are designed to protect and cover electrical wires, hoses, and tubing. This type of covering provides a superior level of protection against abrasion, cuts, and other mechanical damage, and also offers resistance to chemicals, solvents, and UV rays.One of the leading manufacturers of polyester braided sleeving is {{Company Name}}, a company known for its high-quality electrical components. With a focus on innovation and customer satisfaction, the team at {{Company Name}} has developed a range of polyester braided sleeving products that are tailored to meet the needs of various industries.{{Company Name}}’s polyester braided sleeving is available in a range of diameters and colors, making it a versatile option for all types of wiring applications. The sleeves are also easy to install, thanks to their expandable design. They can be easily slipped over wires and cables, providing instant protection.One of the key benefits of polyester braided sleeving is its ability to reduce the risk of electrical fires. Electrical fires can occur when wires are exposed to excessive heat or become damaged due to abrasion or other factors. Polyester braided sleeving can help to prevent this by providing a protective layer that acts as a barrier against heat and other damaging elements.Another advantage of polyester braided sleeving is that it can help to extend the life of electrical wires. When wires are exposed to the elements, they can become worn and damaged over time. This can lead to costly repairs or replacements. By using polyester braided sleeving, wires are protected from the elements, making them last longer and perform better.Polyester braided sleeving from {{Company Name}} is also environmentally friendly. The sleeves are made from a high-quality, recyclable material that is free from harmful chemicals. This makes it an ideal choice for businesses and individuals who are looking for sustainable and eco-friendly solutions.Overall, polyester braided sleeving is a cost-effective and reliable solution for protecting electrical wires and cables. It offers superior protection against abrasion, cuts, and other types of damage, and is easy to install and maintain. With a range of diameters and colors to choose from, {{Company Name}}’s polyester braided sleeving is an excellent choice for businesses and individuals who are looking for quality, reliability, and superior performance.

Durable and Protective High Temperature Braided Sleeving for Various Applications

High Temp Braided Sleeving: The Ultimate Solution for Extreme Temperature ChallengesIn today's business landscape, efficiency, effectiveness, and reliability have become crucial factors for achieving sustainable growth and success. Among a wide range of industries, this is especially true for the aerospace, automotive, electrical, and military sectors where environmental factors, such as high temperatures, can cause significant damage to components and systems.High Temp Braided Sleeving is a game-changer, providing an unmatched solution for such extreme temperature challenges. It is an innovative, flexible, and durable solution that can help protect sensitive components and cables from exposure to high temperatures, chemicals, abrasion, and other environmental factors.What is High Temp Braided Sleeving?High Temp Braided Sleeving is a flexible, lightweight, and highly durable material that can protect cables and wiring from harmful environmental factors. It is made from a variety of materials, including fiberglass, Kevlar, nylon, and other advanced materials that make it resistant to fire, chemicals, and abrasion.The braided wires are treated with an insulating coating that enhances its ability to withstand severe conditions. The material can operate from -70°C to +260°C and can easily expand and contract according to the movement of the components.How Can High Temp Braided Sleeving Help Industries?High Temp Braided Sleeving provides a perfect solution for industries where exposure to harsh environmental factors can cause significant damage to equipment, machinery, and systems. Here are some of the industries that can leverage the benefits of High Temp Braided Sleeving.1. Aerospace IndustryIn the aerospace industry, High Temp Braided Sleeving can protect delicate sensors, cables, and wiring in harsh environmental conditions, such as high temperatures, humidity, and pressure. It can resist fire, chemicals, and abrasion and keep the components safe from any damage.2. Automotive IndustryIn the automotive industry, High Temp Braided Sleeving can protect the cables and wiring in environments where high temperature and vibration can cause them to wear out quickly. The material can withstand the high temperatures of the engine bay and prevent damage to critical components, such as the wiring harnesses.3. Electrical IndustryIn the electrical industry, High Temp Braided Sleeving can protect wires and cables in harsh environments where temperatures, UV radiations, and chemicals can cause damage. It can protect the cables and wiring from abrasion, dust, and other unwanted particles.4. Military IndustryIn the military industry, High Temp Braided Sleeving can protect electronic equipment from harsh environments where military vehicles and aircraft operate. It can resist high temperatures and harsh chemicals, making it the perfect material to protect the cables and wires from damage.Why Choose Our High Temp Braided Sleeving?The High Temp Braided Sleeving offered by our company is made from the highest quality materials, making it one of the most durable and reliable products on the market. Our braided sleeves have various beneficial features that make them suitable for a wide range of applications, including:1. Temperature Resistance: With its superior heat resistance, our High Temp Braided Sleeving can operate in environments up to 260°C.2. Chemical Resistance: Our braided sleeves are highly resistant to chemicals, solvents, and oils, making them an ideal material for use in harsh environments.3. Durable: Our High Temp Braided Sleeving is highly durable and can withstand extensive wear and tear that can damage other materials.4. Flexible: Our braided sleeves are highly flexible and can easily bend and move according to the components' motion, making them perfect for use in tight spaces.5. Easy to Install: Our braided sleeves are easy to install and can be used for different applications, including protecting cables, wiring, hoses, tubing, and other components.ConclusionHigh Temp Braided Sleeving is an ideal solution for many industries facing extreme temperature challenges. It provides ultimate protection to delicate components, cables, and wiring from harsh environmental factors, such as high temperatures, chemicals, and abrasion. Our company offers the highest quality braided sleeves made from the most durable and reliable materials. By leveraging our High Temp Braided Sleeving, industries can enhance efficiency, effectiveness, and reliability and achieve sustainable growth and success.

Protective Sleeves for Wire Harnesses: Importance and Benefits

[Company Introduction] Founded in [year], [Company Name] is a leading manufacturer and supplier of innovative wire harness protective sleeves for various industries worldwide. With a commitment to delivering high-quality products and exceptional customer service, we have established ourselves as a trusted partner for businesses seeking reliable cable management solutions.[Company Name] boasts state-of-the-art manufacturing facilities and a team of highly skilled engineers and technicians. We leverage cutting-edge technology and adhere to stringent quality control measures to ensure that our wire harness protective sleeves meet the highest standards of performance and durability. Our dedication to research and development enables us to continuously update our product offerings, staying ahead of industry trends and demands.[Company Name] takes pride in our commitment to sustainability. We prioritize eco-friendly manufacturing processes, utilizing materials that are recyclable and minimizing waste generation. By adopting a sustainable approach, we recognize our responsibility to protect the environment and contribute to a more sustainable future.Our product range includes a variety of wire harness protective sleeves designed to provide exceptional protection against abrasion, extreme temperatures, chemicals, and other hazards. Whether it's for automotive, aerospace, electronics, or any other industry, our sleeves are engineered to withstand the toughest conditions, ensuring the safe and efficient operation of electrical systems.Our wire harness protective sleeves offer several key advantages, making them an ideal choice for businesses:1. Advanced Material Technology: We utilize advanced materials such as flame-retardant polyethylene terephthalate (PET) and halogen-free materials. These materials are resistant to heat, oil, solvents, and UV radiation, ensuring optimal performance and longevity.2. Enhanced Durability: Our sleeves are designed to withstand a wide range of conditions, including extreme temperatures and harsh environments. Offering excellent resistance to abrasion and chemicals, they provide long-lasting protection to wires and cables.3. Easy Installation: Our sleeves are user-friendly, offering easy installation and removal for efficient maintenance and repair processes. They can be customized to fit various wire harness sizes and configurations.4. Compliance with Industry Standards: Our products meet or exceed industry standards, including flame resistance, electrical conductivity, and RoHS compliance. This ensures that our customers receive products that meet rigorous quality specifications.In addition to our impressive product range, [Company Name] takes pride in our exemplary customer service. We work closely with our clients to understand their specific requirements and provide tailored solutions to meet their unique needs. Our team of dedicated professionals is always available to offer technical assistance and guidance, ensuring a seamless experience from concept to delivery.[News Content - 800 words][Headline][Company Name] Presents Innovative Wire Harness Protective Sleeves for Enhanced Electrical System Safety[Subheading 1][Company Name], a leading manufacturer and supplier of wire harness protective sleeves, unveils its latest range of innovative products aimed at enhancing electrical system safety in various industries.[Paragraph 1]Electrical systems, be it in automotive, aerospace, or electronics, demand robust protection against a wide array of hazards. Understanding the significance of safeguarding the smooth functioning of electrical systems, [Company Name] offers cutting-edge wire harness protective sleeves that are engineered to provide excellent protection against physical wear, extreme temperatures, chemicals, and more.[Subheading 2]Key Features and Benefits[Paragraph 2][Company Name]'s wire harness protective sleeves leverage advanced material technology to ensure optimal performance and durability. The utilization of materials such as flame-retardant polyethylene terephthalate (PET) and halogen-free materials enhances the sleeves' resistance to heat, oil, solvents, and UV radiation. These features make them an ideal choice for businesses operating in demanding environments.[Paragraph 3]Furthermore, the sleeves are designed to offer enhanced durability and resistance to abrasion and chemicals. They can withstand extreme temperatures and harsh conditions, providing long-lasting protection to wires and cables. This durability helps companies reduce maintenance and replacement costs, contributing to overall operational efficiency.[Paragraph 4]Installing and removing wire harness protective sleeves can be a time-consuming and challenging task. However, [Company Name] ensures ease of installation with their user-friendly products. Customizable to fit various wire harness sizes and configurations, these sleeves facilitate efficient maintenance and repair processes, minimizing downtime and ensuring uninterrupted operations.[Subheading 3]Compliance with Industry Standards and Environmental Responsibility[Paragraph 5][Company Name] upholds its commitment to quality through compliance with industry standards. Their wire harness protective sleeves meet or exceed requirements related to flame resistance, electrical conductivity, and RoHS compliance. This ensures that customers receive products that adhere to rigorous quality specifications, guaranteeing the safety and reliability of their electrical systems.[Paragraph 6]In addition to prioritizing product quality, [Company Name] embodies environmental responsibility. The company utilizes eco-friendly manufacturing processes and materials that are recyclable, minimizing their carbon footprint and promoting sustainability. By choosing [Company Name]'s wire harness protective sleeves, businesses contribute to a greener future without compromising on performance and safety.[Subheading 4]Outstanding Customer Service[Paragraph 7]Apart from its remarkable product range, [Company Name] stands out for its exceptional customer service. Their team of dedicated professionals works closely with clients, understanding their specific requirements and providing personalized solutions. With technical assistance and guidance readily available, customers can rely on [Company Name] for a seamless experience from concept to delivery.[Conclusion][Company Name] continues to stand at the forefront of wire harness protective sleeve innovation, catering to diverse industry needs. Their commitment to delivering high-quality products, complying with industry standards, and providing outstanding customer service solidifies their position as a trusted partner for businesses seeking reliable cable management solutions.

Top Quality Fiberglass Fabric for Various Applications

FIBERGLASS FABRIC Revolutionizes the Composite IndustryIntroduction:In today's ever-evolving world, technological advancements have become a driving force behind industrial development. One such breakthrough is the introduction of fiberglass fabric. Over the years, this cutting-edge material has revolutionized the composite industry, paving the way for enhanced strength, durability, and versatility. With its wide range of applications, fiberglass fabric is quickly becoming a go-to choice for engineers, architects, and manufacturers worldwide. In this article, we will explore the transformative impact of fiberglass fabric and delve into the company behind its remarkable success.Fiberglass Fabric: A Game-Changing Material:Fiberglass fabric is a composite made of fine strands of glass intertwined to create a lightweight, yet incredibly strong, material. Engineered with a combination of silica-based minerals and various polymers, fiberglass fabric offers exceptional mechanical properties. It is known for its high tensile strength, excellent resistance to corrosion, and remarkable insulation properties. Additionally, this fabric possesses high dimensional stability, making it an optimal choice for applications in extreme temperature and humidity conditions. With its exceptional versatility, fiberglass fabric finds extensive use in industries such as automotive, aerospace, construction, and marine.Unleashing Boundless Applications:One of the key factors contributing to the popularity of fiberglass fabric is its infinite range of applications. In the automotive sector, this extraordinary material is being used for the manufacturing of car body parts, reducing weight while maintaining structural integrity. With its ability to withstand high pressure and resist chemical degradation, fiberglass fabric plays a crucial role in the oil and gas industry. Moreover, it is widely utilized in the construction of aircraft due to its lightweight nature, enhancing fuel efficiency and reducing emissions. The exceptional strength and durability of fiberglass fabric also make it an ideal choice for the construction of bridges, buildings, and other infrastructure projects. Furthermore, it is extensively employed in the marine industry for boat hulls, deck covers, and reinforcement of various marine structures.Leading the Fiberglass Revolution: Behind the phenomenal success of fiberglass fabric lies {} (Company Name), a pioneering leader in the field. With years of experience and extensive research, {}, company easily stands as the leading provider of top-quality fiberglass fabric. Their commitment to innovation, customer satisfaction, and environmental responsibility has propelled them to the forefront of the industry.{} offers a wide range of fiberglass fabric products, catering to diverse needs and requirements. Their fabric is manufactured using state-of-the-art techniques that ensure exceptional quality and consistency. The company's team of skilled engineers and technicians work tirelessly to develop new and improved products, pushing the boundaries of what is possible with fiberglass fabric. Additionally, {} maintains strict quality control measures, ensuring that each fabric roll meets the highest standards.With a strong emphasis on sustainability, {} takes pride in its eco-friendly manufacturing processes. They strive to reduce waste and energy consumption, making them a responsible choice for environmentally conscious customers. By adhering to stringent safety guidelines, {} ensures the wellbeing of their employees and the communities in which they operate.Conclusion:The revolutionary impact of fiberglass fabric cannot be overstated. Its strength, durability, and versatility have transformed industries and opened up endless possibilities for engineers and manufacturers. {} has emerged as a frontrunner in providing top-quality fiberglass fabric, catering to a wide range of applications. With its commitment to innovation and sustainability, {} is poised to continue leading the fiberglass revolution and shaping a brighter future for the composite industry. The vast potential of fiberglass fabric is only beginning to be fully realized, and its transformative power promises to create an even more advanced and efficient world.

Discover the Benefits of Fiberglass Sleeving for Electrical Applications

[Company Introduction][Company Name] is a leading manufacturer and supplier of high-quality industrial materials. With over [number] years of experience in the industry, we strive to provide our customers with innovative solutions and top-notch products.Our commitment to excellence and customer satisfaction has earned us the trust and loyalty of businesses worldwide. We take pride in our extensive range of products, which includes [product categories]. From electrical insulation materials to mechanical protection solutions, we cater to various industries, meeting their diverse needs and requirements.Our state-of-the-art manufacturing facility, equipped with cutting-edge technology and skilled professionals, ensures that our products are of the highest standard. With a strong emphasis on quality control measures, we conduct rigorous testing at every stage of the production process to ensure optimal performance and reliability.At [Company Name], we believe in sustainable practices and responsible manufacturing. We are committed to minimizing our environmental impact and continuously improving our processes to adopt greener alternatives. Our dedication to sustainability extends to the materials we use, including our range of Fibreglass Sleeving.[Introduction to Fibreglass Sleeving]Fibreglass Sleeving is a versatile and highly durable electrical insulation material that finds applications across various industries. Designed to safeguard electrical components from heat, chemicals, and abrasions, this sleeving provides dependable protection in demanding environments.Key Features of Fibreglass Sleeving:1. High Temperature Resistance: Fibreglass Sleeving is known for its exceptional resistance to high temperatures. This makes it suitable for use in applications where prolonged exposure to heat is expected, such as in motors, transformers, and generators.2. Electrical Insulation: The insulating properties of Fibreglass Sleeving make it ideal for electrical applications, where it effectively prevents current leakage and enhances safety. It ensures the efficient functioning of electrical systems, minimizing the risk of shorts and malfunctions.3. Chemical Resistance: Fibreglass Sleeving demonstrates excellent resistance to a wide range of chemicals, making it an ideal choice for industries that deal with corrosive substances. It provides a protective layer that shields electrical components from chemical damage, extending their lifespan.4. Mechanical Protection: The robust nature of Fibreglass Sleeving offers mechanical protection to wires and cables. It resists wear and tear caused by abrasion, thereby ensuring the longevity of the components and enhancing their reliability.5. Flexibility and Expandability: Fibreglass Sleeving is available in various sizes and configurations, allowing for easy installation and fitting onto different wire diameters. Its expandability ensures a snug fit, offering excellent coverage and protection.Applications of Fibreglass Sleeving:1. Electrical Equipment: Fibreglass Sleeving is widely used in electrical equipment, including motors, generators, transformers, and coils. It ensures insulation, protection, and heat resistance in these critical components.2. Automotive Industry: The automotive industry heavily relies on Fibreglass Sleeving for wire harnessing and insulation purposes. It provides a reliable barrier against heat, abrasion, and chemicals, thereby enhancing the performance and safety of vehicles.3. Electronic Appliances: Fibreglass Sleeving is utilized in electronic appliances such as kitchen appliances, televisions, and computers. It safeguards wiring connections and electrical components from heat and abrasions caused by regular usage.4. Industrial Applications: Various industrial sectors, such as aerospace, manufacturing, and telecommunications, benefit from Fibreglass Sleeving. Its high temperature resistance, electrical insulation, and durability make it a preferred choice for protecting wires and cables in these demanding environments.In conclusion, Fibreglass Sleeving offered by [Company Name] is a reliable and efficient choice for electrical insulation and mechanical protection. With its exceptional performance under high temperatures, chemical resistance, and flexibility, this sleeving ensures the long-term reliability of electrical components in various industries. At [Company Name], we strive to provide our customers with superior products backed by our dedication to quality and sustainability.

Protect Your Wires with High-Temperature Sleeving

High Temperature Wire Sleeving: The Future of Protection for Electrical ComponentsElectrical components are fragile devices that are easily susceptible to damage due to environmental factors. Temperature, humidity, and physical contact are some of the common factors that can damage these parts. That's why a protective covering is necessary to shield them from these factors. High-temperature wire sleeving is a new and efficient method of protecting electrical components that is setting new standards in the industry.One such company that is revolutionizing the sleeve industry is Company X. Company X was established in 2000, and since then, it has been providing customers with high-quality sleeving products that cater to different industries ranging from aerospace, automotive, telecommunications, and military. The company is committed to offering superior products that protect and safeguard electrical components, making it a leader in its industry.The company produces a wide range of high-temperature wire sleeving products to meet different industrial needs. These include products such as fiberglass braided sleeving, silicone coated fiber sleeves, and high-temperature ceramic sleeving. These sleeving products have different properties that allow them to function well in high-temperature environments, protecting wires from the surrounding heat and potential sources of damage.One of the key benefits of high-temperature wire sleeving is its heat-resistant properties. The sleeves are efficient in protecting electrical wires from the damage caused by high temperatures. Electrical wires are known to expose themselves to high temperatures, especially when they transmit high levels of power or run for extended periods. These high temperatures can lead to melting of the wires, corrosion, and degradation of the insulation material leading to a short circuit. High-temperature wire sleeving acts as a barrier, preventing these damaging effects of high temperatures.In addition to their heat-resistant properties, these high-temperature sleeves also provide protection from other environmental factors. For instance, they are waterproof and resistant to moisture. This is particularly important in industrial settings that may expose wires to water damage. The sleeving also protects electrical wires from physical contact, which can lead to breakage, deformation or damage to the insulation material.High-temperature wire sleeving also serves as an excellent insulator. The material used in making the sleeving has excellent insulating properties, preventing current leaks and electrical faults. Insulation also prevents electrical noise from propagating to other parts of the electrical system, which can interfere with the system's performance.Company X's sleeving solutions are designed to cater to the diverse industrial needs of its customers. The company produces custom sizes that are tailored to fit specific types of wires used in particular industries, ensuring that each sleeving piece offers optimum protection and performance.Another significant advantage of high-temperature wire sleeving is its durability. The protective sleeving is made of high-quality materials that are resistant to wear and tear, making them long-lasting. The sleeves can withstand environmental factors such as vibration, corrosion, and physical contact, maintaining their protective properties for an extended period.In conclusion, high-temperature wire sleeving is quickly becoming the go-to solution for protecting electrical components in the industrial sector. Advanced technology and superior materials have enabled Company X to produce high-quality sleeving products that are durable, resistant to environmental damage, and efficient in safeguarding electrical wires from high temperatures. These protective sleeves will continue being a valuable investment for industrial companies seeking reliable, long-lasting, and efficient protection of their electrical components. With the continued advancement of technology, the future of high-temperature wire sleeving looks bright, and companies like Company X will continue to spearhead its development and production.For more information about Company X and its products, visit their website or contact them directly.